The Buying Guide: Screw Air Compressor

Screw air compressors are widely used in numerous applications, be it your own home, or in industries. They are opted for due to their energy efficiency and lower maintenance requirements, which saves up a considerable amount of money. Screw air compressors also consume far less oil than other oil-flooded air compressors you’ll find in the market do.

This article will focus on how these screw air compressors work, their main types, the main differences between rotary screw air compressors and piston air compressors, how to tackle issues related to them, and much more.

Screw Air Compressor Working

We’re going to tell you what a screw air compressor’s working principle is.

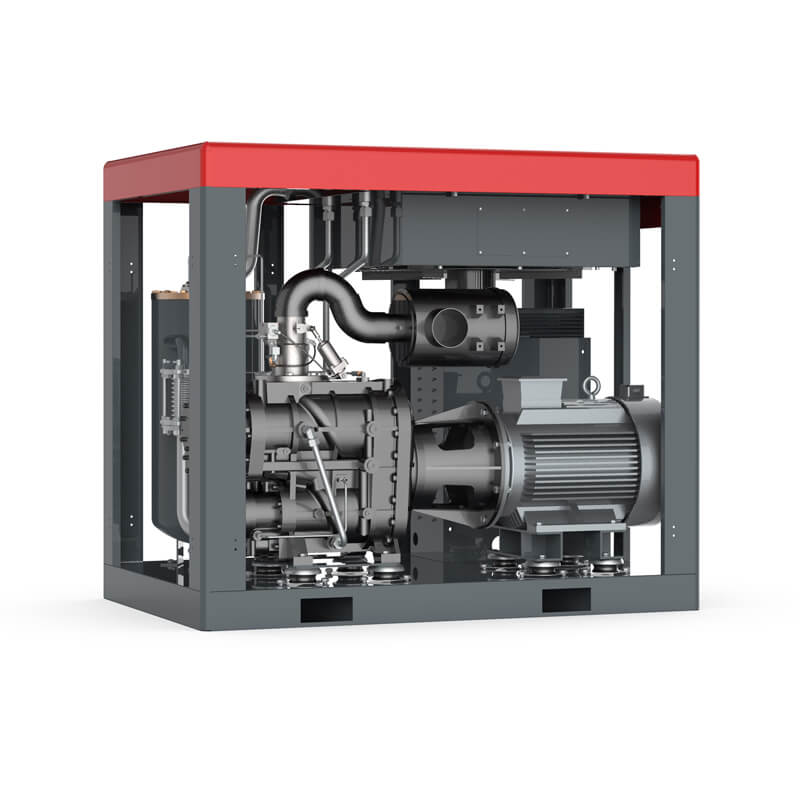

Let’s first take a look at its specific components. In the compressor, there are two rotors present. Mostly one of the rotors is referred to as the male rotor, while the other one is referred to as the female rotor.

Each rotor will consist of lobes and flutes, and how many lobes and flutes each rotor will contain will depend entirely upon the size of the air compressor you’re using. In most cases, however, the female rotor is seen to contain more flutes as compared to the male rotor’s lobes. This is designed in a way to achieve more efficiency.

In order to get a clearer picture, let us describe the function of both rotors in this screw-type air compressor in this way- the male lobe’s function is to move the piston down continuously, while the female flute acts like a cylinder that traps air and reduces space simultaneously.

This air is then transported down through the female rotor, which is immediately compressed as the volume is decreased. This is how, in short, a screwdriver air compressor works.

This air is then trapped until use. When it is to be used, this compressed air is transferred to the required work, through the screw air compressor air pump.

Rotary Screw Air Compressor Types

There are many types of air compressors you’ll come across. Here, we’re going to discuss some of them for you.

Oil-based air compressor

In an oil-based rotary screw air compressor, oil is poured into the screw chamber of the compressor. After the air compressor is used, the oil is taken out by an oil separator.

Oil-free air compressor

An oil-free air compressor does not need oil to be poured in. This type of air compressor does not need oil on its cylinder walls.

Rotary screw air compressor with dryer

At times, there is moisture and aerosol left behind in the compressor. This can alter the efficiency and work performance of the overall screw air compressor. This is what screw air compressors with dryers are for. These air compressors that feature a dryer do not let any vapor or aerosol be left behind, thus, not letting it affect the overall air compressor’s work performance.

Portable rotary screw air compressor

Another common type of air compressor is a portable rotary screw air compressor. This type of air compressor is more of a small rotary screw air compressor, which is ideal for outdoor use, as it is very easy and convenient to move around. However, a screw portable air compressor is not suitable to power up demanding tools and equipment, as this air compressor is not as powerful as a stationary one.

Truck-mounted rotary screw air compressor

You’ll find truck-mounted rotary screw air compressors mostly for automotive, industrial, as well as commercial applications. Such air compressors are highly durable and reliable, as they are made from steel.

If you’re looking for one of the best air compressors, don’t forget to check out Screwfix air compressors.

Screw VS Piston Air Compressor

Screw air compressor and piston air compressor differ greatly. In a screw air compressor, two meshing helical screws are used in order to compress air. On the other hand, a piston compressor makes use of pistons that are driven by a crankshaft.

Now, let’s talk about the main differences between these two types of air compressors. Firstly, the cost of producing compressed air is cheaper when a screw air compressor is used.

On the other hand, not only is the purchasing cost of the piston air compressor high but so is the service cost. If you opt for a screw air compressor, you’ll benefit from lesser noise.

With a screw air compressor, you can utilize several types of modes, such as weekly operation and weekend operation. Moreover, the overall operation is quite simple and convenient, and easy to use. Let’s not forget how reliable and durable screw compressors are compared to piston air compressors.

Rotary Screw Air Compressor Troubleshooting

In case you’re facing issues and problems related to your rotary screw air compressor, this one’s for you. Here, we’ve highlighted one of the common issues faced by individuals regarding their rotary screw air compressor, and how to tackle them:

The air compressor is not starting

In case your rotary screw air compressor doesn’t seem to be starting, you might want to take a look at the power supply, to ensure it is getting enough voltage. Then, check the fuses, temperature, system pressure, as well as voltage supply. You also might want to ensure that all of the wires are tightly connected.

The air compressors shut off after starting

When this happens, the best thing to do is to check the air compressor’s power supply, valve, and wiring. You should check the compressor if it has an adequate oil level, and you might also want to tighten any loose belts that might’ve caught your eye.

Low pressure

In case you notice there is low discharge pressure, analyze the compressor belts, and tighten them if they are loose. Then, you might want to check the air compressor’s voltage supply.

Air compressor consuming too much oil

If your air compressor is taking up a considerable amount of oil than usual, then we advise you to take a look at the sump in order to check if there is an adequate oil level. Then, carefully look at all the lines for any damage or cracks. If none of these work, then you might have to replace the separator with a new one.

In case your problems or issues have still not been solved, then you should take a look at the rotary screw air compressor troubleshooting guide pdf available online.

Screw Air Compressor Availability and Price

If we talk about the price of rotary screw air compressors, then that will depend entirely upon what brand you go for, the model, specifications, horsepower, and size.

For instance, if you go for an air compressor with 5HP, then you can easily find one in the range of $1500 to $5000. However, if you increase the horsepower to 25 HP, then such an air compressor will cost you anywhere between $20,000 and $35,000. Therefore, as the horsepower increases, so does the price.

As for availability, whether you rent one out or purchase a brand new one depends entirely on your budget and usage. In case you have a tight budget, then you should opt for renting one out. However, in case you need an air compressor that you will use more often, then we advise you to purchase a new one. You can easily look up screw air compressors for sale, depending upon where you live. For instance, screw air compressors for sale Australia.